Industrial Simulation & Training

Industrial Simulation & Training Models

The line of fischertechnik simulation models are designed to provide a compact, engaging, and hands-on method for teaching and demonstrating high end automated systems. The line consists of a series of pre-assembled, small scale models, which are designed to replicate—in appearance and function—various automated/robotic machines and systems commonly used in commercial manufacturing.

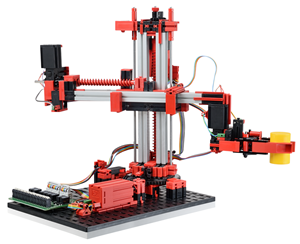

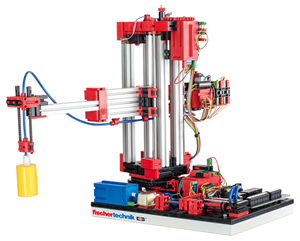

3D-Robot 24v

3-axis robot with gripping forceps. Robot quickly and precisely positions workpieces in three -dimensional space. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

3D-Robot 9v

3-axis robot with gripping forceps. Robot quickly and precisely positions workpieces in three -dimensional space. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

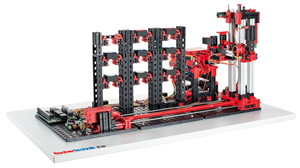

Automated High Bay Warehouse 24v

Transfer station with conveyor belt, with shelf stacker for storing and retrieving special workpiece carriers, and 9 storage spots. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

Automated High Bay Warehouse 9v

Transfer station with conveyor belt, with shelf stacker for storing and retrieving special workpiece carriers, and 9 storage spots. Fully assembled training model, wired to pre-programmed fischertechnik ROBOTICS TXT Controller.

Conveyor Belt 24v

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

Conveyor Belt 9v

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

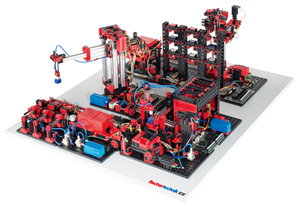

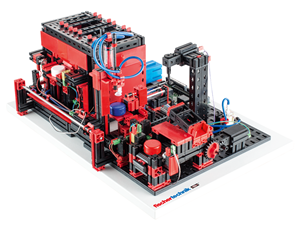

Factory Simulation 24v

The fischertechnik Factory Simulation combines four models --Vacuum Gripper Robot, Automated High Bay Warehouse, Multi-Processing Station with Oven, and the Sorting Line with Color Detection--into one self-contained material cycle.

Workpieces are retrieved from the Automated High Bay Warehouse using the Vacuum Gripper Robot, and then moved to the Multi-Processing Station with Oven. After the work-piece has been processed by this machine, it is then sorted by color in the Sorting Line with Color Detection, before being again moved by the Vacuum Gripper Robot to the Automated High Bay Warehouse for storage. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

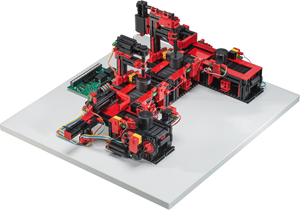

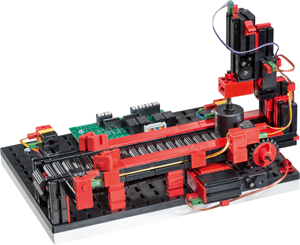

Indexed Line with 2 Machining Stations 24v

U-shaped conveyor line. Features a milling and a drilling station, and four conveyor belt sections. Fully assembled training model for use with PLC (Programmable Logic Controllers) and PLC programming software.

Indexed Line with 2 Machining Stations 9v

U-shaped conveyor line. Features a milling and a drilling station, and four conveyor belt sections. Fully assembled training model, wired to two pre-programmed fischertechnik ROBOTICS TXT Controllers.

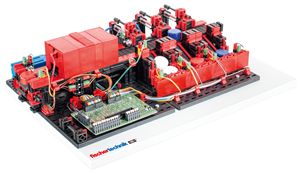

Multi Working Station with Oven 24v

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

Multi Working Station with Oven 9v

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Pre-assembled training model, wired to 2 fully programmed fischertechnik ROBOTICS TXT Controllers.

Punching Machine with Conveyor Belt 24v

Conveyor belt with two light barriers, one machining station, and one workpiece. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

Punching Machine with Conveyor Belt 9v

Conveyor belt with two light barriers, one machining station, and one workpiece. Designed to simulate the movement and punching of workpieces on an automated line. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

Sorting Line with Color Detection 24v

System for detecting workpieces of different colors and sorting them via a conveyor belt into three different storage bins. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

Sorting Line with Color Detection 9v

System for detecting workpieces of different colors and sorting them via a conveyor belt into three different storage bins. Fully assembled training model, wired to pre-programmed fischertechnik ROBOTICS TXT Controller.

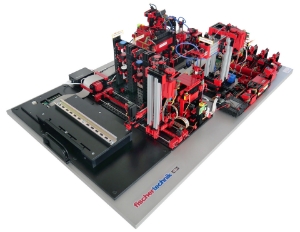

Training Factory Industry 4.0 in 24v

The fischertechnik Training Factory Industry 4.0 – 24V is an extremely flexible, modular, reasonably priced, and highly robust training and simulation model for use with most popular industrial PLCs.

Changes in industrial production driven by digitalization make stronger networking and more relevant information necessary on all production levels. With the fischertechnik Training Factory Industry 4.0, these digitalization activities can be simulated, learned, and applied on a small scale before they are implemented on a large scale.

The fischertechnik Training Factory Industry 4.0 is a 24V simulation model that consists of factory modules including storage and retrieval stations, a Vacuum Gripper robot, High-Bay Warehouse, Multi-Processing Station with Oven, a Sorting Line with Color Detection, an environmental sensor, and a pivoting camera. It is especially designed for exploring and understanding industry 4.0 applications in vocational schools and training as well as for research, teaching and development at universities, in companies, and IT departments.

Training Factory Industry 4.0 in 24v complete with PLC S7-1500--Educational Version (EV required)

Industry 4.0 applications and process flows as a modular training and simulation model

Advantages:

- Including PLC Siemens S7-1500, basic program and ready-made cabling

- Enables in-depth learning through haptic grasping on a realistic production image

- Digital traceability through NFC/RFID, remote monitoring via camera, sensory applications

- Integrated cloud connection with dashboard, control via smart devices, own cloud and dashboard can be integrated, Raspberry Pi 4 with Node-RED interface

- Communication via OPC/UA and MQTT

The fischertechnik learning environment is used for learning and understanding industry 4.0 applications in vocational school and training and for use in research, teaching and development at universities, in companies and IT departments. The simulation depicts the ordering process, the production process, and the delivery process in digitized and networked process steps.

Training Factory Industry 4.0 in 24v with PLC Connection Board

Industry 4.0 applications and process flows as a modular training and simulation model

Advantages:

- Including PLC connection board and ready wiring on model and PLC side

- Enables in-depth learning through haptic grasping on a realistic production image

- Digital traceability through NFC/RFID, remote monitoring via camera, sensory applications

- Integrated cloud connection with dashboard, control via smart devices, own cloud and dashboard can be integrated, Raspberry Pi 4 with Node-RED interface

- Communication via OPC/UA and MQTT

The fischertechnik learning environment is used for learning and understanding industry 4.0 applications in vocational school and training and for use in research, teaching and development at universities, in companies and IT departments. The simulation depicts the ordering process, the production process, and the delivery process in digitized and networked process steps.

Training Factory Industry 4.0 in 9v

The fischertechnik Training Factory Industry 4.0 is extremely flexible, modular, reasonably priced, and highly robust training and simulation model.

Changes in industrial production driven by digitalization make stronger networking and more relevant information necessary on all production levels. With the fischertechnik Training Factory Industry 4.0, these digitalization activities can be simulated, learned, and applied on a small scale before they are implemented on a large scale.

The fischertechnik Training Factory Industry 4.0 is a 9V simulation model that consists of factory modules including storage and retrieval stations, a Vacuum Gripper robot, High-Bay Warehouse, Multi-Processing Station with Oven, a Sorting Line with Color Detection, an environmental sensor, and a pivoting camera. It is especially designed for exploring and understanding industry 4.0 applications in vocational schools and training as well as for research, teaching and development at universities, in companies, and IT departments.

Vacuum Gripper Robot 24v

3-axis robot with vacuum gripper. Works quickly and precisely, to position workpieces in three-dimensional space. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

Storage and Transport Case

For safe storage and transport of fischertechnik Factory Simulation and Training Factory Industry 4.0 models

Advantages:

- A practical custom case for safe storage and transport of fischertechnik factory models

- Insert once - done! The lower part of the factory is fully functional, only the hood has to be moved.

- Inside lined with soft foam padding

- 3 inside zipper pockets for stowing accessories

- 4 tiltable carrying handles

Quality Control w/AI - 9V version

Visualize AI models and make them easily comprehensible

- Ideal training, simulation and demonstration model for education and research

- Visualization of AI systems, machine learning and neural networks

- Networking of theory and practice for a sustainable learning result

- Already built, stable training model. Mounted on stable wooden plate, packaging of the model in stable cardboard box

- IMPORTANT: For all operations, a power supply 9V/2,5A is required (sold separately)

Artificial intelligence in research, education and industry

The use of artificial intelligence in industry, education and research is becoming more and more important. The Quality Control with AI System model from fischertechnik is ideal for visualising this complex subject in a hands-on way since it creates a sustainable learning experience by linking theory and practice.

Agile Production Simulation 24V

The fischertechnik Agile Production Simulation 24V with S7-1200 PLCs is designed as an ideal training model tailored for Higher Education and professional Industrial training applications. Consists of individual modules such as incoming and outgoing goods, high-bay warehouse, milling station, drilling station, and quality assurance with AI. A driverless transport system flexibly transports workpieces between the individual stations and ensures a flexible production process that can be adapted to customer requirements.

AVAILABLE TO ORDER NOW!